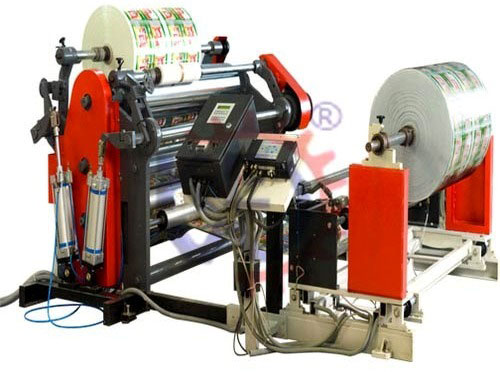

Rotogravure Printing Machine

KEW manufactures, exports & supplies precision quality Rotogravure Printing Machine, which is suitable for printing plastic and paper packing materials like Polyethylene, Polypropylene Bag, Cellophane, Paper Roll, BOPP Film, LDPE, OPP, etc. from Ahmedabad, Gujarat, India.

KEW Rotogravure Printing Machine are the most suitable & efficient printing Equipment for Printing of Paper Bags, Plastic Bags, Milk Pouches, Food Bags, Super market Hand Bags, Vest Bags, Cloth Bags, Confectionery Wrappers, Film Pouches, etc.

We have been successfully manufacturing, exporting & supplying all types of Rotogravure Printing Machine since last 25 years from Ahmedabad, Gujarat, India. We are winner of 3 times National Award and 2 times International Award for Quality manufacturing. For Rotogravure Printing Machine, we have processed all types of material like Polyester, BOPP, LD, PVC, Paper, Aluminum Foil, Film, etc. We have more than 105 installation of Rotogravure Printing Machine in India and overseas like Saudi Arabia, UAE, Dubai, Sharjah, South Africa, Nigeria, Ghana, Congo, Kenya, Zambia, Sri Lanka, Bangladesh, Malaysia, Pakistan, Nepal, Russia, Thailand, Indonesia, Brazil, Colombia, Venezuela, Argentina, Mexico, Canada, etc.

KEW offers new high speed Rotogravure Printing Machines – Model – KEW–HSRG–001 Semi Auto. The machine has great aesthetic looks with great performance at high speed.

Technical Specifications of Rotogravure Printing Machine:

- Max. web width : 800/1000/1200/1400/1600 mm

- Maximum operating speed : 150 / 200 meters /min.

- Print repeat range : 350 1000mm

- Printing materials : Foil, Paper, Polyester, Bopp, PP, PVC, LDPE etc.

- Drying source : Electrical /thermic fluid / gas

- Dryer : Closed type single side drying oven

- Dimension of printing station: 600 x 3200 x 65mm

- Registration longitudinal : Motorized ball screw

- Lateral : Manual motorized (Optional)

- Tension control feedback : Through dancer roll & load cell

Salient Features:

- Modular printing station each being complete in it for easy adoptability of when required.

- Specially designed compensator roll with ball screw to achieve extra-fine registration.

- All rollers are dynamically balanced to ensure noise and vibration free operation for accurate printing.

-

The unique design of the impression roller ensures even application of pressure across the entire width of the substrate.

Close type single side drying oven & special type one & one type counter flow arrangement for exhaust and air blowing to get high speed drying.

- Individual control panel at each station for all electrical controls & pneumatic system.

3 Drive Servo based automatic web tension control system with dancer roll feedback & load cell sensing for in - feed, out-feed & main & digital drives for unwind & rewind

Optional Attachments:

- Video scope

- Automatic registration control system

- 7 Drive with turret

- Ink circulation system

- Auto splicing.

- PLC base functions.

- PID control with exhaust with drive controls.

- Lubrication system

We Also Offer:

- Rotogravure printing machine with Electronics Line Shaft (ELS)

- Shaft less cylinder chucking system

Ultrasonic edge guide sensor with electric motor actuating. Unwind tension control by dancer feedback and load cell indication. In feed system to maintain tension between unwind and first printing unit. Unwinder, Rewinder, in-feed, out-feed and main drive tension control by HMI touch screen / PLC control.

Out-feed system to maintain tension between last printing and Rewinder. Rewinding tension control by dancer feedback and load cell indication same as controlled by unwinding side through HMI Touch screen.

Individual inspection box with light provided on each station to see the registration of printing of each station while machine is running.

- Motorized web video inspection system with traverse bar mounting.

Automatic length and side-lay register control system with full colored touch screen to controlled registration during running press. Provided with high resolution color camera, monitor to see registration while running.

A.C. Digital Servo Motor with servo drive to get higher accuracy of registration at higher speed for rotogravure press. 3 Drive and 5 Drive Servo Option available.

私達のプロダクト

- グラビア印刷の印字機

- ラミネーション機械

- Flexo の印字機

- コータ

- スリッター Rewinder 機械

- 点検巻き戻す機械

- 巻き戻す機械の治療

- インクジェット・プリンタのための巻く巻き戻す機械

- ハイドロ Pneumo 網のアライナシステム

- 網のアライナシステム

- 網の指導システム

- ロール伸張の包む機械

- BOPP テープ打抜き機

- 中心の打抜き機

- 端の指導システム

- ローラーアセンブリの追跡

- Unwinder 機械

- Rewinder 機械

照会

Awards

私達について

私達の会社は柔軟材包装及び変換分野でよく経験されます。 私達はでグラビア印刷の印字機、ラミネーション機械、 Flexo の印字機、コータ、スリッター Rewinder 機械、巻き戻す機械を、インクジェット・プリンタ治療する、点検巻き戻す機械をハイドロ Pneumo 網のアライナシステム、網のアライナシステム、網の指導システム、ロール伸張の包む機械、 BOPP テープ打抜き機、中心の打抜き機、ローラーアセンブリを、 Unwinder 機械追跡する、端の指導システムのための巻取り機の Rewinder 機械 Rewinder 機械製造し、輸出し、そして供給します。 会社は非常に良質の機械類およびサービスを提供しています。

多くを見て下さい

私達に

KRISHNA ENGINEERING WORKS

Punit Nagar Crossing Road, Ghodasar,

Ahmedabad-380050, Gujarat, INDIA

+91-9327940232

遠ファクシミリ : +91-79-25895305

+91-79-40085305

電子メール : info@krishnaengineeringworks.com

krishnaengineeringworks@yahoo.com

ウェブサイト連絡して下さい : www.krishnaengineeringworks.com

Manual Slitting Rewinding Machine

Manual Slitting Rewinding Machine