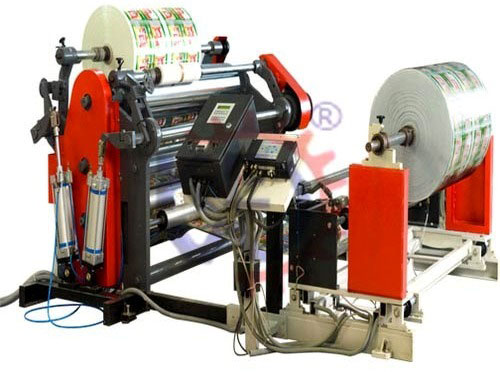

Lamination Machine

KEW manufactures, exports & supply Lamination Machine which laminates various types of materials like Plastic, Paper, LDPE, BOPP, etc. from Ahmedabad, Gujarat, India.

We have been successfully manufacturing, exporting & supplying all types of Lamination Machine since last 25 years from Ahmedabad, Gujarat, India. We are winner of 3 times National Award and 2 times International Award for Quality manufacturing. For Lamination Machine, we have processed all types of material like Polyester, BOPP, LD, PVC, Paper, Film, etc. We have more than 100 installation of Lamination Machine in India and overseas like Saudi Arabia, UAE, Dubai, Sharjah, South Africa, Nigeria, Ghana, Congo, Kenya, Zambia, Sri Lanka, Bangladesh, Malaysia, Pakistan, Nepal, Russia, Thailand, Indonesia, Brazil, Colombia, Venezuela, Argentina, Mexico, Canada, etc.

The Principle

Film Laminating Machine use polyester (PET) film as its base film, adhesive (EVA resin) is evenly applied on one side of the polyester (PET) film. After special processing, it turned into advanced packing material, and it is widely used for the laminating and protection of material like identification card, historical accounts, photos, pictures, credit cards and important documents. After laminating, the material has the unique function like water resistance, alteration resistance, damp resistance, worm resistance and mildew resistance on general acid-base. What's more, it is stiff, smooth and pleasing to one's eyes, since it has good transparency.

The Use

Laminated materials are widely used for Plastic & Paper Materials like Milk Pouches, Food Packets, Wafer Pouches, Cloth Bags, etc. Our Lamination Machine are used for Laminating above all types of materials.

KEW offers High Speed Industrial Laminating Machine with great accuracy and organized performance. The machine is easy to handle, install and operate.

Type of Laminating Machine:

- Dry Laminating Machine

- Wet Laminating Machine

- Heat Laminating Machine

- Sheet Laminating Machine

- Roll Laminating Machine

SALIENT FEATURES:

- Heavy duty C.I. Cast iron & Heavy fabricated structure.

- Gravure type coating system.

- Cantilever type impression pressure assembly actuated with pneumatic piston for rubber roll Doctor Blade and Nip Roller.

- Fully insulated imported special glass wool sheet fitted in the panel (Top side & Bottom) for controlling heat loss.

- One & One Slit type counter air flow arrangement, Divided equally are placed against roller for proper web support.

- Exhaust are distributed through-out the length of drying chamber & individual exhaust duct for each zone.

- Digital temperature controller with indicator & PT 100 sensor for each Zone.

- Inside heating for Nip Steel roller.

- Heavy duty Shaft types fix Rewinder with motor.

- KEW SRA Web system for controlling the Web after the drying tunnel & two web for primary & Secondary unwind.

EXAMPLE OF COATING METHODS

- Top nip fed three roll reverse roll coater

- Gravure reverse roll coater

- Gravure roll coating with oscillating doctor blade

- Reverse roll coating with nip feed

- Kiss coating with air knife

- Kiss coating with Mayer bar

- Five roll (smooth) coating

Technical Specifications:

- Web Width : 400 – 2400mm

- Unwind Rewind Diameter : 600 - 1000mm

- Hot Air Temp : 50 – 150 / 250°C

- Machine Speed : 60 – 200 M/Min.

- Heat Source : Hot Air Generator (Optional)

- Exhaust : 5 HP

- Synchronized Drive : 5 HP/5 / 7.5,10 / 3 HP for Coater, Nip, Rewind & Positive Drive (Optional)

- Material to be Laminated : Polyester/Poly/Paper/BOPP/Aluminum Foil/HDPE Fabrics etc.

UNWIND STATION:

- Tension control Brake Unit with load cell feedback (Electrical/Pneumatic).

- Moveable unwind with web guide.

COATING UNIT:

- Independent A.C. Drive.

- Pre – Heating / Exhaust.

DRYING CHAMBER:

- Load cell feedback for coating & Nip.

- Pneumatic lifting of top door.

- Cat walk for full length drying chamber.

- Programmable Temperature Control.

- Positive tunnel drive.

HOT AIR GENERATOR:

- Diesel / Coal or Wood Fired Air Heater / Thermic fluid Heater with Blower.

DRY LAMINATING UNIT:

- Web Chaser

REWIND STATION:

- A. C. synchronize Drive with Load cell.

- Center winding system/ Surface.

OPTIONAL ATTACHMENT:

- Air Shaft

- Pull roll assembly ( In feed drive )

- May bar / Reverse roll, Air knife Three roll.

- Wet Lamination arrangement.

- Extra blower & Exhaust Individual for each zone.

- Chill Roll.

- Bow Roller.

- Ink Circulating with Viscosity Control.

- Touch Screen Operated control for all drive.

私達のプロダクト

- グラビア印刷の印字機

- ラミネーション機械

- Flexo の印字機

- コータ

- スリッター Rewinder 機械

- 点検巻き戻す機械

- 巻き戻す機械の治療

- インクジェット・プリンタのための巻く巻き戻す機械

- ハイドロ Pneumo 網のアライナシステム

- 網のアライナシステム

- 網の指導システム

- ロール伸張の包む機械

- BOPP テープ打抜き機

- 中心の打抜き機

- 端の指導システム

- ローラーアセンブリの追跡

- Unwinder 機械

- Rewinder 機械

照会

Awards

私達について

私達の会社は柔軟材包装及び変換分野でよく経験されます。 私達はでグラビア印刷の印字機、ラミネーション機械、 Flexo の印字機、コータ、スリッター Rewinder 機械、巻き戻す機械を、インクジェット・プリンタ治療する、点検巻き戻す機械をハイドロ Pneumo 網のアライナシステム、網のアライナシステム、網の指導システム、ロール伸張の包む機械、 BOPP テープ打抜き機、中心の打抜き機、ローラーアセンブリを、 Unwinder 機械追跡する、端の指導システムのための巻取り機の Rewinder 機械 Rewinder 機械製造し、輸出し、そして供給します。 会社は非常に良質の機械類およびサービスを提供しています。

多くを見て下さい

私達に

KRISHNA ENGINEERING WORKS

Punit Nagar Crossing Road, Ghodasar,

Ahmedabad-380050, Gujarat, INDIA

+91-9327940232

遠ファクシミリ : +91-79-25895305

+91-79-40085305

電子メール : info@krishnaengineeringworks.com

krishnaengineeringworks@yahoo.com

ウェブサイト連絡して下さい : www.krishnaengineeringworks.com

Manual Slitting Rewinding Machine

Manual Slitting Rewinding Machine